Cruise Control: Root Locus Controller Design

Key MATLAB commands used in this tutorial are: tf , rlocus , feedback , step

Contents

System model

The transfer function model for the cruise control problem is given below. Please see the Cruise Control: System Modeling page for the derivation.

(1)![$$

P(s) = \frac{V(s)}{U(s)} = \frac{1}{ms+b} \qquad [ \frac{m/s}{N} ]

$$](Content/CruiseControl/Control/RootLocus/html/CruiseControl_ControlRootLocus_eq15895515400129359059.png)

System parameters

For this example, let's assume that the parameters of the system are

(m) vehicle mass 1000 kg

(b) damping coefficient 50 N.s/m

(r) reference speed 10 m/s

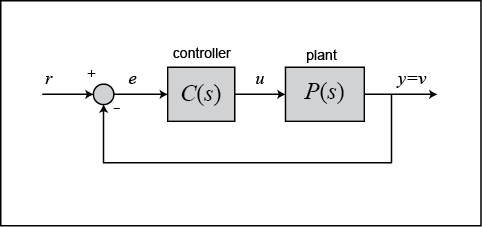

and the block diagram of a typical unity feedback system is shown below.

Performance specifications

- Rise time < 5 sec

- Overshoot < 10%

- Steady-state error < 2%

Proportional control

Recall from the Introduction: Root Locus Controller Design page, the root-locus plot shows the locations of all possible closed-loop poles when a single gain is varied from zero to

infinity. Thus, only a proportional controller,  , will be considered to solve this problem. The closed-loop transfer function becomes:

, will be considered to solve this problem. The closed-loop transfer function becomes:

(2)

Also, from the Introduction: Root Locus Controller Design page, we know that the MATLAB command sgrid can be used to display an acceptable region of the root-locus plot. To use the sgrid, both the damping ratio,  , and the natural frequency,

, and the natural frequency,  , need to be determined first. The following two equations will be used to find the damping ratio and the natural frequency:

, need to be determined first. The following two equations will be used to find the damping ratio and the natural frequency:

(3)

(4)

where

= Natural Frequency [rad\s]

= Natural Frequency [rad\s]

= Damping Ratio

= Damping Ratio

= Rise time [s]

= Rise time [s]

= Maximum Overshoot

= Maximum Overshoot

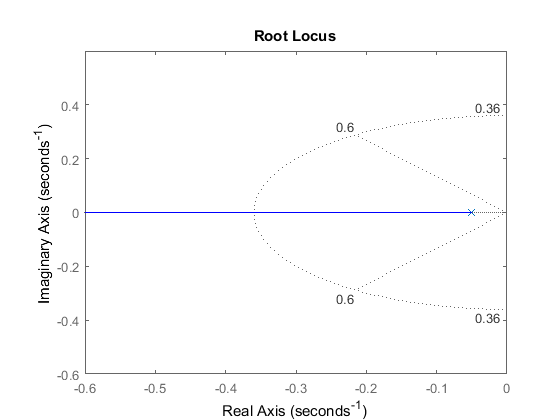

One of our design criteria is to have a rise time of less than 5 seconds. From the first equation, we see that the natural frequency must be greater than 0.36. Also using the second equation, we see that the damping ratio must be greater than 0.6, since the maximum overshoot must be less than 10%.

Now, we are ready to generate a root-locus plot and use the sgrid to find an acceptable region on the root-locus. Create a new m-file and enter the following commands.

m = 1000;

b = 50;

r = 10;

s = tf('s');

P_cruise = 1/(m*s+b);

rlocus(P_cruise)

axis([-0.6 0 -0.6 0.6]);

sgrid(0.6, 0.36)

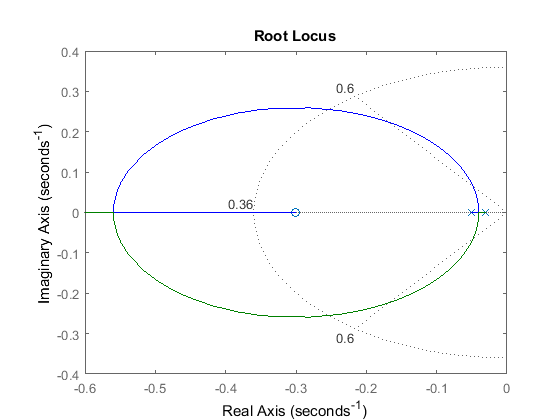

The two dotted lines in an angle indicate the locations of constant damping ratio ( =0.6); the damping ratio is greater than 0.6 in between these lines and less than 0.6 outside the lines. The semi-ellipse

indicates the locations of constant natural frequency (

=0.6); the damping ratio is greater than 0.6 in between these lines and less than 0.6 outside the lines. The semi-ellipse

indicates the locations of constant natural frequency ( =0.36); the natural frequency is greater than 0.36 outside the semi-ellipse, and smaller than 0.36 inside.

=0.36); the natural frequency is greater than 0.36 outside the semi-ellipse, and smaller than 0.36 inside.

We can then find a gain to place the closed-loop poles in the desired region by employing the rlocfind command. Add the code [Kp,poles]=rlocfind(P_cruise) onto the end of your m-file to help you choose a specific loop gain. After running in the command window, you should see

a prompt asking you to pick a point on the root-locus plot. Since you want to pick a point in between dotted lines ( >0.6) and outside the semi-ellipse (

>0.6) and outside the semi-ellipse ( >0.36), click on the real axis just outside the semi-ellipse (around -0.4) as indicated by the cross mark in the following

figure.

>0.36), click on the real axis just outside the semi-ellipse (around -0.4) as indicated by the cross mark in the following

figure.

After doing this, you should see the following output in the MATLAB command window.

Select a point in the graphics window

selected_point =

-0.4002 + 0.0019i

Kp =

350.2419

poles =

-0.4002

Note that the value returned from your MATLAB command window may not be exactly the same, but should at least have the same order of magnitude. This returned value can be used as the gain for the compensator and the closed-loop step response can be generated as follows.

Kp = 350.2419; sys_cl = feedback(Kp*P_cruise,1); t = 0:0.1:20; step(r*sys_cl,t)

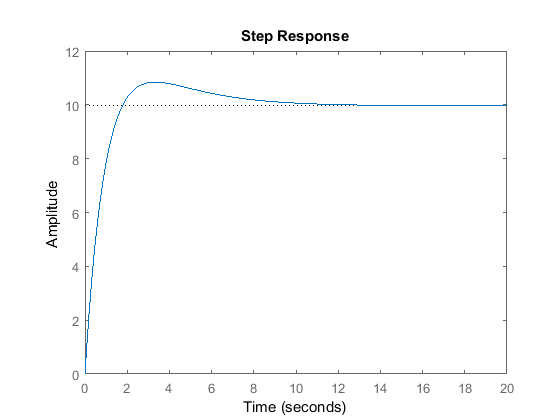

With the gain Kp you just chose, the rise time and the overshoot criteria have been met; however, a steady-state error of more than 10% remains.

Lag controller

To reduce the steady-state error, a lag controller will be added to the system. The transfer function of the lag controller is:

(5)

The closed-loop transfer function (not including  ) now becomes:

) now becomes:

(6)

Finally, including the loop gain  , the closed-loop transfer function becomes:

, the closed-loop transfer function becomes:

(7)

If you read the "Lag or Phase-Lag Compensator using Root-Locus" section in the Lead and Lag Compensator Design page, the pole and the zero of a lag controller need to be placed close together. Also, it states that the steady-state error

will be reduced by a factor of  . For these reasons, let

. For these reasons, let  equal 0.3 and

equal 0.3 and  equal 0.03.

equal 0.03.

Create a new m-file, and enter the following commands.

zo = 0.3;

po = 0.03;

s = tf('s');

C_lag = (s+zo)/(s+po);

rlocus(C_lag*P_cruise);

axis([-0.6 0 -0.4 0.4])

sgrid(0.6,0.36);

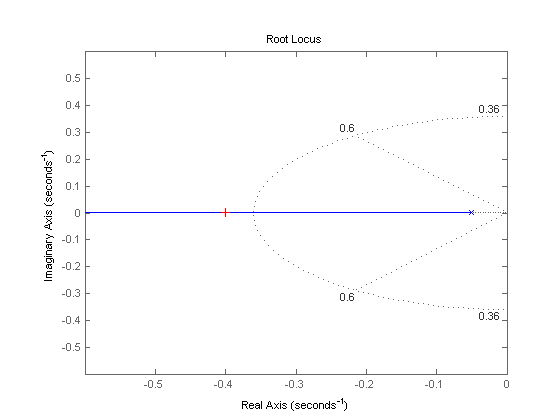

Using the rlocfind command again, we can choose a new loop gain  . Enter the code [Kp,poles]=rlocfind(C_lag*P_cruise) into the command window and click on the real axis around -0.4 as shown in the following figure.

. Enter the code [Kp,poles]=rlocfind(C_lag*P_cruise) into the command window and click on the real axis around -0.4 as shown in the following figure.

After doing this, you should see the following output in the MATLAB command window.

Select a point in the graphics window

selected_point =

-0.4002 - 0.0012i

Kp =

1.2936e+03

poles =

-0.9733

-0.4003

We can then generate the new closed-loop step response as follows.

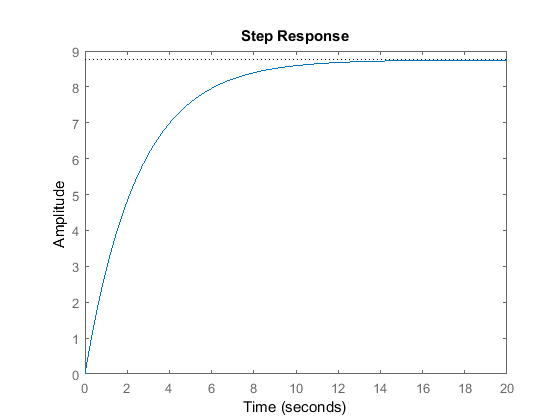

Kp = 1293.6; sys_cl = feedback(Kp*C_lag*P_cruise,1); t = 0:0.1:20; step(r*sys_cl,t) axis([0 20 0 12])

As you can see, the steady-state error has been reduced to near zero. The overshoot is a result of the zero added in the lag

controller. For now all of the design criteria have been met and no further iterations are needed; however, you should experiment

with different  and

and  values to see what their effect is on the closed-loop system response.

values to see what their effect is on the closed-loop system response.