Aircraft Pitch: PID Controller Design

Key MATLAB commands used in this tutorial are: controlSystemDesigner

Contents

From the main problem, the open-loop transfer function for the aircraft pitch dynamics is

(1)

where the input is elevator deflection angle  and the output is the aircraft pitch angle

and the output is the aircraft pitch angle  .

.

For the original problem setup and the derivation of the above transfer function please refer to the Aircraft Pitch: System Modeling page.

For a step reference of 0.2 radians, the design criteria are the following.

- Overshoot less than 10%

- Rise time less than 2 seconds

- Settling time less than 10 seconds

- Steady-state error less than 2%

Recall from the Introduction: PID Controller Design page that the transfer function for a PID controller is the following.

(2)

We will implement combinations of proportional ( ), integral (

), integral ( ), and derivative (

), and derivative ( ) control in the unity-feedback architecture shown below in order to achieve the desired system behavior.

) control in the unity-feedback architecture shown below in order to achieve the desired system behavior.

In particular, we will take advantage of the automated tuning capabilities of the Control System Designer within MATLAB to design our PID controller. First, enter the following code at the command line to define the model of our

plant  . Refer to the Aircraft Pitch: System Modeling page for the details of getting these commands.

. Refer to the Aircraft Pitch: System Modeling page for the details of getting these commands.

s = tf('s');

P_pitch = (1.151*s+0.1774)/(s^3+0.739*s^2+0.921*s);

Proportional control

Let's begin by designing a proportional controller of the form  . The Control System Designer we will use for design can be opened by typing controlSystemDesigner(P_pitch) at the command line. The Control System Designer window will initially open with the root locus plot, open-loop Bode plot, and closed-loop step response plot displayed for

the provided plant transfer function with controller

. The Control System Designer we will use for design can be opened by typing controlSystemDesigner(P_pitch) at the command line. The Control System Designer window will initially open with the root locus plot, open-loop Bode plot, and closed-loop step response plot displayed for

the provided plant transfer function with controller  , by default.

, by default.

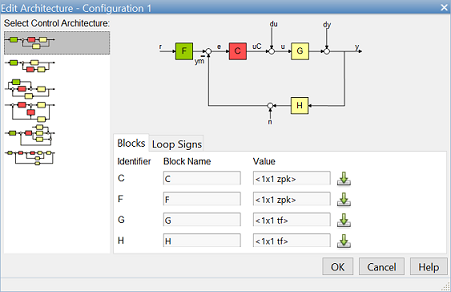

The Edit Architecture button in Control System Designer window displays the architecture of the control system being designed as shown below. This default agrees with the architecture we are employing.

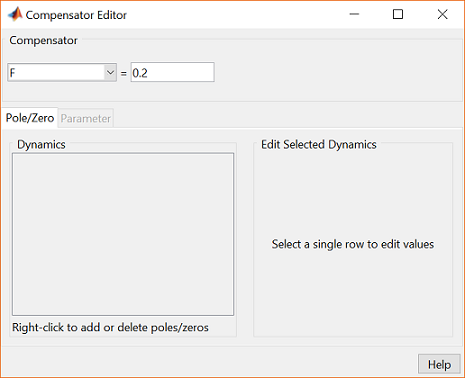

Since our reference is a step function of 0.2 radians, we can set the precompensator block  equal to 0.2 to scale a unit step input to our system. This can be accomplished from the Compensator Editor window, which can be opened by right-clicking on the plot and then selecting Edit Compensator. Specifically, choose F from the drop-down menu in the Compensator portion of the window and set the compensator equal to 0.2 as shown in the figure below.

equal to 0.2 to scale a unit step input to our system. This can be accomplished from the Compensator Editor window, which can be opened by right-clicking on the plot and then selecting Edit Compensator. Specifically, choose F from the drop-down menu in the Compensator portion of the window and set the compensator equal to 0.2 as shown in the figure below.

To begin with, let's see how the system performs with a proportional controller  set equal to 2. The compensator

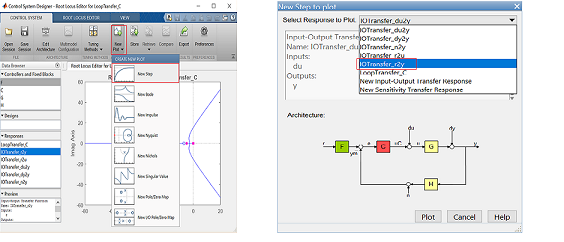

set equal to 2. The compensator  can be defined in the same manner as the precompensator, just choose C from the drop-down menu in the Compensator portion of the window instead of F. Then set the compensator equal to 2. To see the performance of our system with this controller, move to the IOTransfer_r2y:step tab. If you have accidentally closed this tab, you can re-open it from the Control System Designer window by clicking on the New Plot menu and selecting New Step. In response, a new window titled New Step to plot will appear. From the Select Responses to Plot menu, then choose IOTransfer_r2y and click the button Plot as shown below.

can be defined in the same manner as the precompensator, just choose C from the drop-down menu in the Compensator portion of the window instead of F. Then set the compensator equal to 2. To see the performance of our system with this controller, move to the IOTransfer_r2y:step tab. If you have accidentally closed this tab, you can re-open it from the Control System Designer window by clicking on the New Plot menu and selecting New Step. In response, a new window titled New Step to plot will appear. From the Select Responses to Plot menu, then choose IOTransfer_r2y and click the button Plot as shown below.

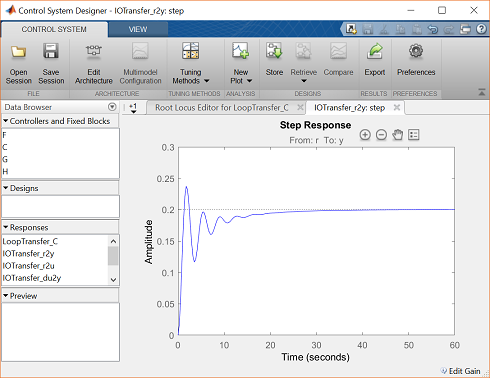

A window will then open with the following step response displayed.

Examination of the above shows that aside from steady-state error, the given design requirements have not been met. The gain

chosen for  can be adjusted in an attempt to modify the resulting performance through the Compensator Editor window. Instead, we will use the Control System Designer to automatically tune our proportional compensator. In order to use this feature, go to the Tuning Methods menu of the MATLAB toolstrip and choose PID Tuning under the Automated Tuning menu. Then select a Controller type of P and Select Loop to Tune as LoopTransfer_C as shown in the figure below (our architecture has only one loop).

can be adjusted in an attempt to modify the resulting performance through the Compensator Editor window. Instead, we will use the Control System Designer to automatically tune our proportional compensator. In order to use this feature, go to the Tuning Methods menu of the MATLAB toolstrip and choose PID Tuning under the Automated Tuning menu. Then select a Controller type of P and Select Loop to Tune as LoopTransfer_C as shown in the figure below (our architecture has only one loop).

There are two options that can be chosen from the Tuning method drop-down menu, Robust response time or Classical design formulas. The Robust response time algorithm automatically tunes the PID parameters to balance speed of response and robustness. It can tune all parameters for any type of PID controller. It can be used for design of plants that are stable, unstable, or integrating. However, the Classical design formulas algorithm requires a stable or integrating plant and cannot tune the derivative filter. If you select Classical design formulas algorithm, then in the Formula drop-down menu a range of options can be seen. These options range from heuristic techniques, like Ziegler-Nichols, to numerical approaches that search over all possible control gains to minimize some identified performance index. For our example, choose the Robust response time algorithm. Then in the Design mode drop-down menu, you can choose Time or Frequency. Since our design requirements are expressed in the time-domain, we select the Design mode as Time. Since, our rise time is expected to be less than 2 seconds, try specifying a Response Time of 1.5 seconds.

Once all of the tuning settings have been chosen, then click the Update Compensator button. The algorithm then chooses a proportional gain of  = 1.1269. This controller meets the rise time requirement, but the settle time is much too large. You can attempt requiring

a faster response time (move the slider to the right), however, this will result in an increase in overshoot and oscillation.

The proportional controller does not provide us a sufficient degree of freedom in our tuning, we need to add integral and/or

derivative terms to our controller in order to meet the given requirements.

= 1.1269. This controller meets the rise time requirement, but the settle time is much too large. You can attempt requiring

a faster response time (move the slider to the right), however, this will result in an increase in overshoot and oscillation.

The proportional controller does not provide us a sufficient degree of freedom in our tuning, we need to add integral and/or

derivative terms to our controller in order to meet the given requirements.

PI control

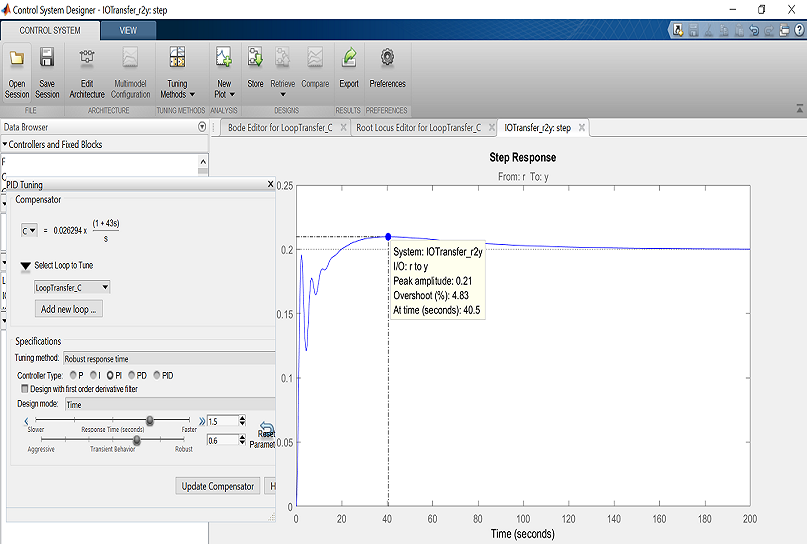

Recalling the information provided in the Introduction: PID Controller Design tutorial, integral control is often helpful in reducing steady-state error. In our case, the steady-state error requirement is already met. For purposes of illustration, let's design a PI controller anyway. We will again use automated tuning to choose our controller gains as we did above, only now we will select a Controller type of PI. Everything else will be left unchanged. Clicking on the Compensator Update button then produces the following controller.

(3)

This transfer function is a PI compensator with  = 0.0263 and

= 0.0263 and  = 1.13. The resulting closed-loop step response is shown below.

= 1.13. The resulting closed-loop step response is shown below.

From inspection of the above, notice that the addition of integral control helped reduce the average error in the signal more quickly (the error changes sign around 20 seconds), but it didn't help reduce the oscillation. Let's try also adding a derivative term to our controller.

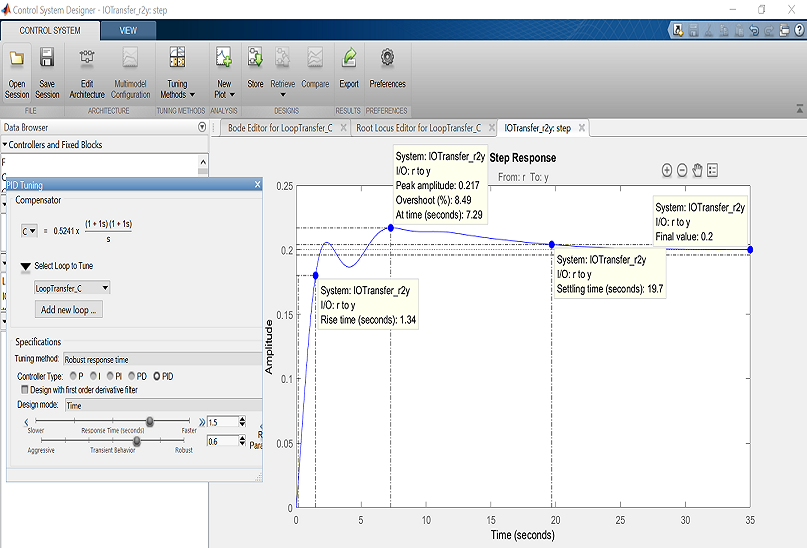

PID Control

Again recalling the lessons we have learned in the Introduction: PID Controller Design tutorial, increasing the derivative gain  in a PID controller can often help reduce overshoot. Therefore, by adding derivative control we may be able to reduce the

oscillation in the response a sufficient amount that we can then increase the other gains to reduce the settling time. Let's

test our hypothesis by changing the Controller type to PID and again click the Update Compensator button. The generated controller is shown below.

in a PID controller can often help reduce overshoot. Therefore, by adding derivative control we may be able to reduce the

oscillation in the response a sufficient amount that we can then increase the other gains to reduce the settling time. Let's

test our hypothesis by changing the Controller type to PID and again click the Update Compensator button. The generated controller is shown below.

(4)

This transfer function is a PID compensator with  = 0.5241,

= 0.5241,  = 1.0482, and

= 1.0482, and  = 0.5241. The resulting closed-loop step response is shown below.

= 0.5241. The resulting closed-loop step response is shown below.

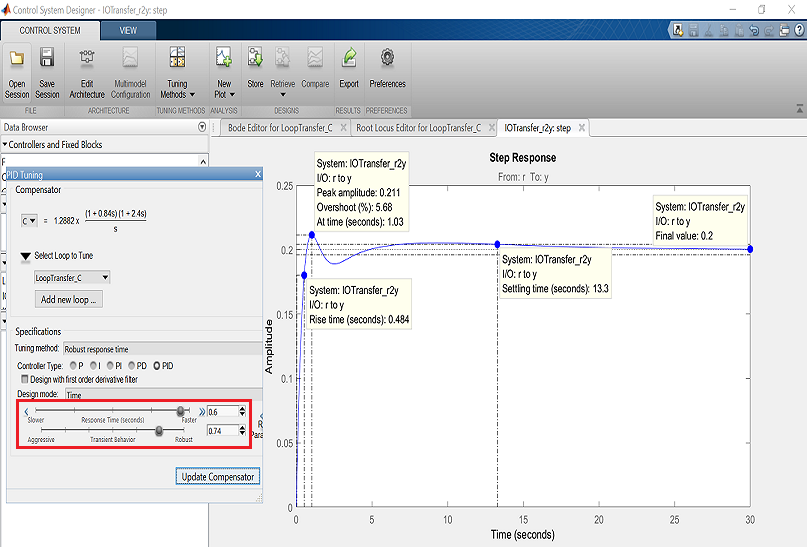

This response meets all of the requirements except for the settle time which at 19.7 seconds is larger than the given requirement of 10 seconds. Reducing the Response Time requirement (moving the slider to the right) will make the response faster, while moving the Transient Behavior slider towards Robust will help reduce the oscillation. The resulting PID controller for the shown settings is given below.

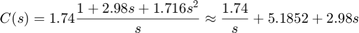

(5)

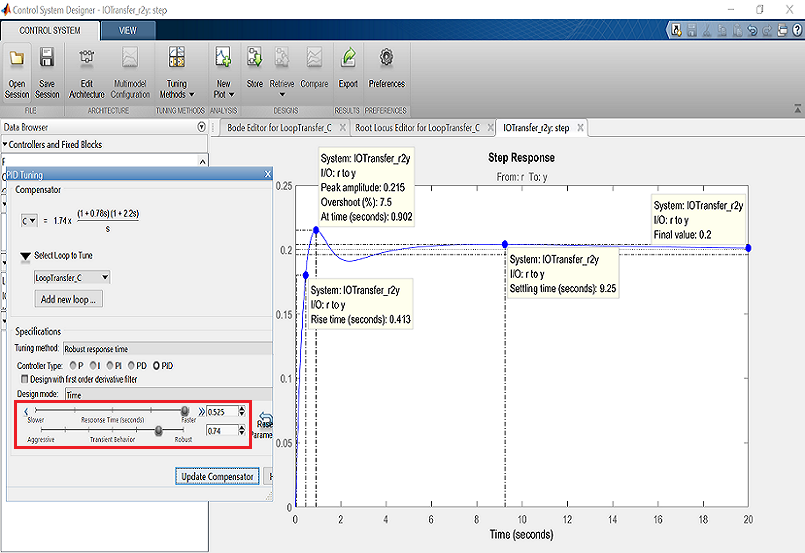

Here we can see that moving both sliders to the right made the response faster and reduced the oscillation. However, the settling time is still greater than the required 10 seconds. We again try increasing the required speed of response; we have some room to spare on overshoot. The resulting PID controller for the settings shown below is the following.

(6)

This response meets all of the given requirements as summarized below.

- Overshoot = 7.5% < 10%

- Rise time = 0.413 seconds < 2 seconds

- Settling time = 9.25 seconds < 10 seconds

- Steady-state error = 0% < 2%

Therefore, this PID controller will provide the desired performance of the aircraft's pitch.